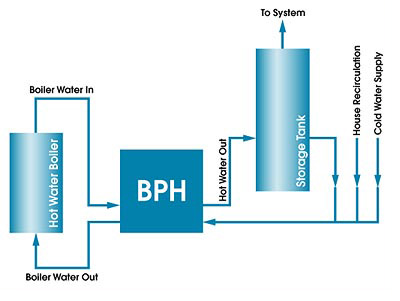

The BPH / PFH Series water heaters are designed to work in conjunction with condensing or specialty hydronic boilers. The plate type heat exchanger maximizes the heat transfer between the boiler water and the domestic water returning water to the boiler lower than the traditional u-bend heat exchangers allowing these heaters can use less gpm of boiler water and low temperature boiler water. The BPH / PFH is with out a storage tank for use instantaneously or piped to an existing storage tank. BPH / PFH water heaters have the ability to heat up to 5,000,000 BTU/hr of hot water.

-

Standard Equipment

-

Advantages

- Designed to be used with condensing boilers

- Increase the boiler’s efficiency by allowing the condensing boiler to condense

- Lower return temperatures to the boiler

- Operate the boiler at a lower temperature

Cemline Packaged Plate Boiler Water Fired Water Heaters are a perfect choice for domestic water heating systems using hydronic boilers including cast iron, copper tube, water tube, or specialty high efficiency boilers. The BPH uses a brazed plate heat exchanger for smaller loads, while the PFH uses a plate & frame heat exchanger for larger loads. The BPH/PFH heat exchanger allows these boilers to operate more efficiently since the BPH/PFH heat exchanger can return the boiler water to the hydronic boiler at lower temperatures than the traditional u-bend heat exchanger. The boiler water can be returned to the boiler as low as 90°F from the BPH/PFH water heater.

Cemline Packaged Plate Water Heaters (BPH/PFH) are completely packaged and ready for use. The BPH/PFH can be used in conjunction with an existing tank or used as an instantaneous water heater. The heaters come complete and require only connection to services.>

The BPH/PFH heat exchanger has a high heat transfer rate allowing for maximum heat transfer between the boiler water and the domestic water. As the heat is transferred from the boiler water to the domestic water, the boiler water can experience large temperature drops through the heat exchanger. The BPH/PFH can achieve larger temperature drops through the heat exchanger requiring less gallons per minute of boiler water than a traditional U-bend heat exchanger that is performing a 20°F delta T on the boiler water side. The large temperature drops occur without laminar flow on the boiler water side of the heat exchanger. The heat exchanger can even allow for temperature crosses between the boiler water outlet and the domestic water outlet temperature, meaning the domestic water outlet temperature can be greater than the returned boiler water temperature.

The boiler can be run at lower temperatures with the BPH/PFH’s ability to perform temperature crosses and to take large delta T’s as a lower boiler water temperature can be used to make domestic hot water.

swh2-advantage-newCemline Corporation Brazed Plate Water Heaters are available with a storage tank either a cement lined STONESTEEL® or 316-L stainless steel vessel in sizes 60, 120, 200, 300, 500, and 680 gallon capacity. See Cemline SPH brochure for more details.

The Cemline BPH/PFH comes factory standard with a 2-way electronically operated control valve. The 2-way electronically operated control valve allows for close temperature control of the water heater by modulating flow of the boiler water through the heat exchanger. The BPH/PFH can achieve +/-2°F with a steady state flow and +/- 4°F under normal operating conditions. The 1000:1 turn down ratio of the control valve allows for accurate control of these water heaters.

The Cemline BPH/PFH can be used for a variety of heat recovery systems or in hot water or chilled water systems.

WARNING: BPH/PFH water heaters are not recommended for water with hardness over 140 parts per million. If water hardness exceeds 140 ppm, either put a water softener in the system

-

Components

STEAM AS THE ENERGY SOURCE

STANDARD EQUIPMENT

- Cem-Trol II