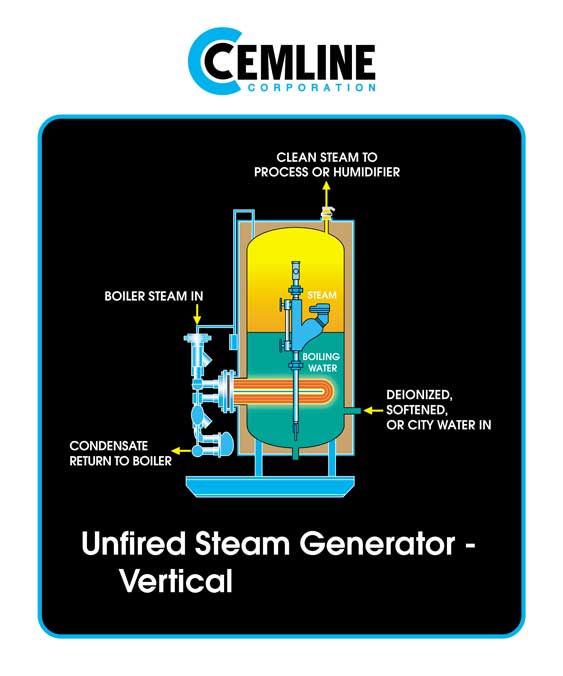

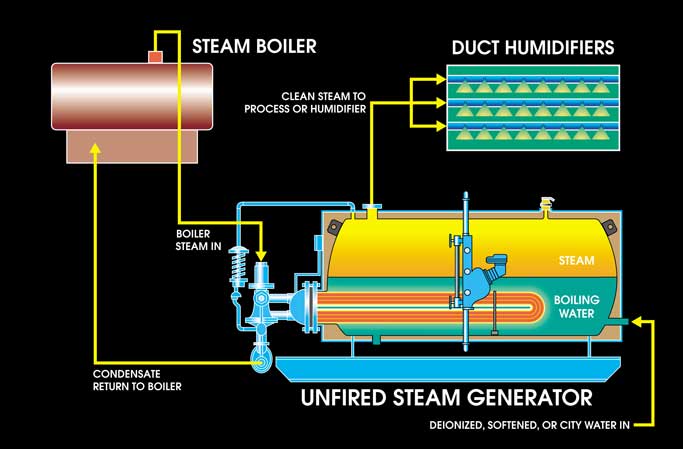

CEMLINE® Unfired Steam Generators are designed to produce clean steam with steam or high temperature hot water as an energy source for use where there is a need to produce clean steam from boiler steam or high temperature hot water.

-

Standard Equipment

ASME Code Constructed National Board Registered Storage Tank

CEMLINE Unfired Steam Generators are constructed and stamped in accordance with ASME code and bear the UB stamp as required by the ASME code. All vessels are registered with the National Board of Boiler and Pressure Vessel Inspectors and a compliance certificate is furnished. Unfired Steam Generators to generate steam 40 psig or greater will be 100% X-Rayed and heat treated in accordance the ASME code

Stainless Steel Construction

CEMLINE Unfired Steam Generators can be constructed of stainless steel when no condensate is returned and there is 100% make up, such as in steam humidification. A stainless steel USG would also be used to provide steam for sterilizers, food processing, pharmaceutical, and clean room applications where deionized or reverse osmosis water is used as feedwater.

Carbon Steel Construction

CEMLINE Unfired Steam Generators can be constructed with a carbon steel shell and steel components. These Unfired Steam Generators would typically be used when the condensate is returned to the boiler and there is little or no make up water. Carbon steel Unfired Steam Generators are typically used in building heating systems and in humidification where the feedwater is not corrosive.

Fiberglass Insulation

CEMLINE Unfired Steam Generators are furnished with 3″ thick fiberglass insulation. This high quality insulation is an extremely reliable means of minimizing heat loss.

20 Gauge Steel Jacket with Hammertone Enamel Finish

CEMLINE Unfired Steam Generators are neatly and attractively covered with a 20 gauge steel jacket over the fiberglass insulation. The jacket protects the insulation and is professionally painted with superior quality enamel which provides an easy to maintain surface.

Structural Support Skid Base

CEMLINE Unfired Steam Generators are mounted on a structural skid designed as a permanent base. This skid is pre-engineered to allow correct support for the Unfired Steam Generator.

ASME Pressure Relief Valve

CEMLINE Unfired Steam Generators are provided with one or more ASME Section I pressure relief valve(s) sized to relieve the total BTU input of the heating coil.

Boiler Steam Pressure Gauge

CEMLINE Unfired Steam Generators are furnished with a large, easily readable pressure requirements.

U-Bend Coil

U-bend coils are constructed with copper, copper nickel, or stainless steel tubes. The selection of tubing material depends upon specific job requirements. The sizing section of this interactive catalogue will assist in selecting the correct tubing material.

Gauge Glass

CEMLINE Unfired Steam Generators are furnished with a gauge glass to allow monitoring of the water level in the vessel.

Steam Separator

A Steam Separator is factory supplied to dry the steam prior to being introduced into the clean steam line.

High Pressure Cutoff

CEMLINE Unfired Steam Generators are furnished with an adjustable high pressure cut off wired to close the control valve in the event of over pressure. The high pressure cut off also has an adjustable differential.

Level Control/Low Water Cutoff

CEMLINE Unfired Steam Generators are furnished with a combination feedwater control/ low water cut off. This level control will allow the correct water level to be maintained in the vessel and will also shut the generator down in the event of low water.

FeedWater Solenoid with Check Valve

As the boiler makes steam, it is necessary to replenish the boiled off water. A solenoid valve, which opens and closes from the water level controller signal, is required. A solenoid feed system requires the feedwater pressure must be at least 10 psi greater than the steam pressure in the Unfired Steam Generator. If there is less than 10 psi pressure differential, a feedwater pump must be used. A check valve is supplied between the solenoid valve and the unfired steam generator.

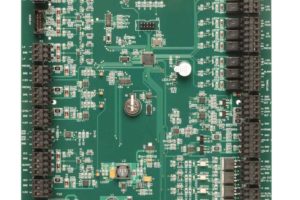

Solid State Operating Control

CEMLINE Model 2001 Solid State Steam Control Module incorporates operating and limit functions in one solid state controller. The controller features a LED display of the pressure and on board settings of high and low pressure safety cut off and alarms. The 2001 SSCM simplifies the control of the Unfired Steam Generator, enhances the look of the product, and follows industry trend to solid state controls.

Alarm Bell

An alarm bell is furnished to sound an alarm in the event of either low water or high pressure. An alarm silencing relay allows manual pressing of a button to silence the alarm bell, but red warning light remains on until the alarm condition is corrected.

Remote Start/Stop

This feature allows the Packaged Water Heater to be started or stopped from a remote location. Typically this would be accomplished from the Building Automatic System (BAS). Requires a dry contact suitable for 24 Vac and 1 amp.

-

Components

STEAM AS THE ENERGY SOURCE

STANDARD EQUIPMENT

Pilot Operated

A pilot operated valve can only be used with steam as the energy source. Pilot operated valves use steam pressure as the energy to modulate the control valve. Steam from upstream of the valve is directed into a pilot valve. This pilot valve has an adjustable set point and pressure sensor sensing generated steam pressure. The pilot valve compares the set point to the sensed pressure and regulates the amount of steam passing through the pilot to the diaphragm in the bottom of the control valve. The steam pressure on the diaphragm opens the valve. A pilot operated valve has a constant bleed line leading from the diaphragm to the downstream side of the valve. When the pilot valve senses that the desired pressure is reached it closes; this does not allow any more steam to pressurize the diaphragm in the bottom of the control valve. The bleed line allows any steam pressurizing the diaphragm to be relieved and the valve closes. In the event of high pressure or loss of building power the limit control closes the steam line from the pilot to the valve which closes the valve. With a supply pressure of up to 15 PSI, 3 PSI is the minimum pressure drop permitted across the valve. With a supply pressure from 16 to 31 PSI, 10 PSI is the minimum pressure drop permitted across the valve. With a supply pressure from 31 PSI and above, 20 PSI is the minimum pressure drop permitted across the valve.

Pneumatic (Air) Operated Control Valve

Air operated valves use building control air pressure to modulate the control valve. The air signal is brought to an adjustable set point temperature sensing controller with a temperature sensing bulb in the heated water. The temperature sensing controller compares the set point to the sensed temperature. The controller regulates the amount of air that passes to the pneumatic actuator of the valve to modulate the valve. This allows steam to pass into the heater coil to maintain the set point of the controller. When the set point is achieved, no air is passed through the temperature sensing controller and the valve is closed. In the event of high temperature or loss of building power, the limit control shall close the air line to the valve and vent any air in the actuator to atmosphere which closes the valve.

Electronic Control Valve

Electronically operated control valves use a solid state temperature sensor which is wired to an electronic control module. The electronic control module has an adjustable set point. The control module compares the set point with the sensed temperature and sends an electric signal to a magnetic linear actuator on the control valve. The magnetic linear actuator modulates the control valve and regulates the amount of boiler water through the valve to maintain the set point of the controller. When the set point is achieved, the controller sends a signal to the valve actuator and the valve closes. In the event of high temperature loss or loss of building power, the limit control closes the electric power to the controller which closes the valve.

Steam Traps

CEMLINE provides float and thermostatic traps for both the drip and main trap. Float and thermostatic traps are acknowledged as the correct traps to use with continuously modulating control valves. Float and thermostatic traps provide immediate drainage of condensate and include a built in thermostatic air vent for venting air. The drain orifice is designed to provide a water seal and eliminate the loss of any live steam under all load conditions. Float and thermostatic traps should not be used to lift condensate.

Inlet Stream Strainer

Strainers are “Y” type with blow down connection and easily removable stainless steel strainer screen.

Source Steam Pressure Gauge

Large, easily readable pressure gauges to read both the source and generated steam pressure.

Vacuum breaker

A vacuum breaker will be mounted in the coil head and will break any vacuum which might occur when the steam is condensed.

OPTIONAL EQUIPMENT

MAKE UP WATER FEEDING OPTIONS

Feedwater Pump/Condensate Receiver

As the boiler makes steam, it is necessary to replenish the boiled off water. This method uses a feedwater pump which is connected to the make up water line and is started and stopped from a signal from the level controller. A solenoid valve and check valve is supplied between the pump and the unfired steam generator.

Automated Blow Down - Timer Method

Unfired Steam Generators using city water will build up an accumulation of minerals in the boiler. These minerals must be disposed by a blowdown system. The blowdown system can simply be a manual blowdown where the maintenance person would manually blow off for a set period of time for a set frequency. It is advantageous to offer an automatic blowdown system. The simplest automatic blowdown system is one that operates from timers. The CEMLINE 2001 SSCM has a built in interval and duration timer wired to a blowdown solenoid valve. The owner/operator can set an interval between blowdowns in a range from 1 to 160 hours and a blowdown duration range of 1 to 250 seconds. The automatic blowdown is a fairly simple system. The automatic timer blowdown requires the owner/operator of the Unfired Steam Generator to do some analysis to determine what duration and interval he/she wishes to have his blowdown occur. *Note: Most municipalities do not allow high temperature discharge directly into the sewer system. CEMLINE offers a type “CBO” centrifugal blow-off/condensate cooler which will receive the blow down, flash the blow down to steam, and cool the condensate going to drain.

Automated Blow Down - Total Dissolved Solids Method

There is a more sophisticated system, which samples the boiler water and blows the boiler down when the dissolved solids exceed the set point. This is a time sample method which measures the total dissolved solids by opening the blowdown valve for an adjustable time period and measuring the blow off for dissolved solids. If the total dissolved solid exceeds the trip point, the motorized valve will remain open until the fresh water make up dilutes the boiler water to a safe level of total dissolved solids. *Note: Most municipalities do not allow high temperature discharge directly into the sewer system. CEMLINE offers a type “CBO” centrifugal blow-off/condensate cooler which will receive the blow down, flash the blow down to steam, and cool the condensate going to drain.

Automated Blow Down Location - Surface Blowdown

The unfired steam generator is a distiller creating pure water in the form of steam and leaving behind the minerals and dissolved solids in the water inside the steam generator. As more steam is produced the concentration of minerals and dissolved solids increase inside the steam generator. The concentration of dissolved solids will increase in the water until saturation point is reached. Then, the water can no longer hold all of the dissolved solids and some begin to drop out of the water in the form of suspended solids forming sludge or scale on the tube bundle and vessel. Scale formation on the tube bundle will reduce the capacity of the unfired steam generator.

Higher concentrations of dissolved solids may bring about carry over of make-up water in the form of wet steam. As the total dissolved solids increase so does the surface tension of the water causing the steam bubbles to adhere to themselves making it more difficult for the steam bubbles to burst as they rise to the surface of the boiling water. Therefore, the concentration of dissolved solids tends to be increased at or near top of water level in the steam generator. Reducing the concentration of dissolved solids and suspended solids in the steam generator will provide the desired capacity and dryness of steam.

A Surface Blowdown can be used to remove dissolved solids from the steam generator. Automatic blowdown controls such as a TDS control or timed blowdown can be mounted at the surface allowing the removal of dissolved solids from the water in the generator. Typically surface blowdowns are performed more frequently than bottom blowdowns.

Automated Blow Down Location - Bottom Blowdown

Higher levels of suspended solids may be found in harder make-up water conditions. Suspended Solids tend to collect in the lower part of the unfired steam generator and form scale on the tube bundle. Removal of these suspended solids can be accomplished by bottom blowdown.

Automatic Bottom blowdown controls can be mounted on the bottom blowdown.Centrifugal Boiler Blow Off/Condensate Cooler

CEMLINE blow down/condensate coolers are designed to receive blow down from a steam boiler, flash the blow down to steam, and cool the condensate going to drain.

High Water Cut Off

In some unusual situations, it is possible for the feedwater to fail which could cause the Unfired Steam Generator to fill with water and flood the entire system. To prevent this from happening, CEMLINE CORPORATION® offers, as an option, a high water cut-off to close a feedwater ball valve if a high water condition occurs. This option consists of a level control connected to a high level switch. The high level switch will send a signal to either an air operated ball valve or an electrically operated ball valve mounted in the feedwater line. These valves are power to open, spring to close

BOILER WATER AS THE ENERGY SOURCE

STANDARD EQUIPMENT

Pneumatic (Air) Operated Control Valve

An air operated valve can be used with hot water as the heating medium. Air operated valves use building control air pressure to modulate the control valve. The air signal is brought to an adjustable set point temperature sensing controller with a temperature sensing bulb in the heated water. The temperature sensing controller compares the set point to the sensed temperature. The controller regulates the amount of air that passes to the pneumatic actuator of the valve to modulate the valve. This allows boiler water to pass into the heater coil to maintain the set point of the controller. When the set point is achieved, no air is passed through the temperature sensing controller and the valve is closed. In the event of high temperature or loss of building power, the limit control shall close the air line to the valve and vent any air in the actuator to atmosphere which closes the valve.

Electronic Control Valve

Electronically operated control valves use a solid state temperature sensor which is wired to an electronic control module. The electronic control module has an adjustable set point. The control module compares the set point with the sensed temperature and sends an electric signal to a magnetic linear actuator on the control valve. The magnetic linear actuator modulates the control valve and regulates the amount of boiler water through the valve to maintain the set point of the controller. When the set point is achieved, the controller sends a signal to the valve actuator and the valve closes. In the event of high temperature or loss of building power, the limit control closes the electric power to the controller which closes the valve.

Two Way Valve

A two way valve modulates from fully closed to fully open varying the amount of hot water circulated through the coil to maintain the desired output temperature. When closed the two way valve may cause a change in the heating water loop pressure.

Three Way Valve

A three way valve modulates from directing all heating water through the coil to directing no heating water through the coil, varying the amount of hot water circulated through the coil to maintain the desired output temperature. The pressure drop in the heating system will be relatively constant with a three way valve.

HTHW Thermometer

The dial type thermometer will monitor HTHW temperature.

MAKE UP WATER FEEDING OPTIONS

Feedwater Pump/Condensate Receiver

As the boiler makes steam, it is necessary to replenish the boiled off water. This method feeds the water from a boiler feed pump unit with a condensate tank. The condensate tank is fed with make up water and condensate. It operates on a signal from the level controller on the Unfired Steam Generator which starts a pump that feeds the make up water into the Unfired Steam Generator. When the water level in the Unfired Steam Generator is satisfied, an electrical signal from the level controller signals the water feed pump to close. The feedwater pump pressure must be 15 psi greater than the generated steam pressure. A solenoid valve and check valve is supplied between the pump and the unfired steam generator.

FeedWater Pump

As the boiler makes steam, it is necessary to replenish the boiled off water. This method uses a feedwater pump which is connected to the make up water line and is started and stopped from a signal from the level controller. A solenoid valve and check valve is supplied between the pump and the unfired steam generator.

AUTOMATIC BLOW DOWN OPTIONS

Automated Blow Down - Timer Method

Unfired Steam Generators using city water will build up an accumulation of minerals in the boiler. These minerals must be disposed by a blowdown system. The blowdown system can simply be a manual blowdown where the maintenance person would manually blow off for a set period of time for a set frequency. It is advantageous to offer an automatic blowdown system. The simplest automatic blowdown system is one that operates from timers. The CEMLINE 2001 SSCM has a built in interval and duration timer wired to a blowdown solenoid valve. The owner/operator can set an interval between blowdowns in a range from 1 to 160 hours and a blowdown duration range of 1 to 250 seconds. The automatic blowdown is a fairly simple system. The automatic timer blowdown requires the owner/operator of the Unfired Steam Generator to do some analysis to determine what duration and interval he/she wishes to have his blowdown occur. *Note: Most municipalities do not allow high temperature discharge directly into the sewer system. CEMLINE offers a type “CBO” centrifugal blow-off/condensate cooler which will receive the blow down, flash the blow down to steam, and cool the condensate going to drain.

Automated Blow Down - Total Dissolved Solids Method

There is a more sophisticated system, which samples the boiler water and blows the boiler down when the dissolved solids exceed the set point. This is a time sample method which measures the total dissolved solids by opening the blowdown valve for an adjustable time period and measuring the blow off for dissolved solids. If the total dissolved solid exceeds the trip point, the motorized valve will remain open until the fresh water make up dilutes the boiler water to a safe level of total dissolved solids. *Note: Most municipalities do not allow high temperature discharge directly into the sewer system. CEMLINE offers a type “CBO” centrifugal blow-off/condensate cooler which will receive the blow down, flash the blow down to steam, and cool the condensate going to drain.

Automated Blow Down Location - Surface Blowdown

The unfired steam generator is a distiller creating pure water in the form of steam and leaving behind the minerals and dissolved solids in the water inside the steam generator. As more steam is produced the concentration of minerals and dissolved solids increase inside the steam generator. The concentration of dissolved solids will increase in the water until saturation point is reached. Then, the water can no longer hold all of the dissolved solids and some begin to drop out of the water in the form of suspended solids forming sludge or scale on the tube bundle and vessel. Scale formation on the tube bundle will reduce the capacity of the unfired steam generator.

Higher concentrations of dissolved solids may bring about carry over of make-up water in the form of wet steam. As the total dissolved solids increase so does the surface tension of the water causing the steam bubbles to adhere to themselves making it more difficult for the steam bubbles to burst as they rise to the surface of the boiling water. Therefore, the concentration of dissolved solids tends to be increased at or near top of water level in the steam generator. Reducing the concentration of dissolved solids and suspended solids in the steam generator will provide the desired capacity and dryness of steam.

A Surface Blowdown can be used to remove dissolved solids from the steam generator. Automatic blowdown controls such as a TDS control or timed blowdown can be mounted at the surface allowing the removal of dissolved solids from the water in the generator. Typically surface blowdowns are performed more frequently than bottom blowdowns.Automated Blow Down Location - Bottom Blowdown

Higher levels of suspended solids may be found in harder make-up water conditions. Suspended Solids tend to collect in the lower part of the unfired steam generator and form scale on the tube bundle. Removal of these suspended solids can be accomplished by bottom blowdown.

Automatic Bottom blowdown controls can be mounted on the bottom blowdown.Centrifugal Boiler Blow Off/Condensate Cooler

CEMLINE blow down/condensate coolers are designed to receive blow down from a steam boiler, flash the blow down to steam, and cool the condensate going to drain.

High Water Cut Off

In some unusual situations, it is possible for the feedwater to fail which could cause the Unfired Steam Generator to fill with water and flood the entire system. To prevent this from happening, CEMLINE CORPORATION offers, as an option, a high water cut-off to close a feedwater ball valve if a high water condition occurs. This option consists of a level control connected to a high level switch. The high level switch will send a signal to either an air operated ball valve or an electrically operated ball valve mounted in the feedwater line. These valves are power to open, spring to close.

- CUT-AWAY

-

Steam-Trol

Buit-in PID Control Signal

PID Control Signal used to modulate an electronic control valve or to control I-P transducer modulating an air operated control valve. The PID controller allows for precise pressure control of the unfired steam generator.

Built-In LCD Touch Screen Display

The STEAM-TROL® features an easy to read and operate LCD touch screen display. The STEAM-TROLdisplay indicates pressure set point, operating pressure, PID voltage output, and level control output. The STEAM-TROL® touch screen display has an easy to navigate menu system for adjusting the settings of the unfired steam generator.

Built-in On-Off Switch

Allows for local on-off and is convenient for service in the unlikely event service is required.

Built-in Alarm Horn

The alarm horn will sound and fault LED will light on high pressure, low water, or low pressure. The STEAM-TROL® also features an alarm silence relay which will silence the alarm but not the fault light when the generator is being serviced. When the fault is cleared, both the alarm and fault light will automatically reset.

Built-in Timer for Timed Blow Down

If the timed blowdown option is selected, the interval and duration of blow down can easily be selected in the STEAM-TROL®.

Built-in Relay for Water Feed

The STEAM-TROL® operates in conjunction with the level control to signal the feedwater solenoid or feedwater pump to maintain the correct water level in the unfired steam generator.

Built-in Modulating Water Feed

The STEAM-TROL® operates in conjunction with the level control to signal the to a modulating feedwater valve to maintain the correct water level in the unfired steam generator.

Built-in Operating Pressure Readout

The STEAM-TROL features an easy to read LCD digital readout of the operating pressure.

Built-in High Pressure Cut-Off and Alarm

In the event of high pressure the STEAM-TROL® will close the source steam or HTHW supply valve and sound an alarm.

Built-in Low Pressure Alarm

If activated, the STEAM-TROL® will sound an alarm if a low pressure condition occurs.

Built-in LED Display of Functions and Alarms

The STEAM-TROL® is designed for the user to tell at a glance how the system is operating. The built in LED displays make troubleshooting simple.

Built-in Remote Pressure Setting

Built-in Remote Pressure Setting Building Automation System can remotely set the operating pressure using a 4-20 mA signal.

Built-in Remote Pressure Read-Out

Building Automation System can remotely set the operating pressure using a 4-20 mA signal.

Built-in MODBUS RTU to communicate with BAS (Building Automation System) of Functions and Alarms

This control allows for simple and reliable interface with the BAS via MODBUS RTU via a RS-485 connection so the BAS can monitor the unfired steam generator from a remote location.

Built-in Contact to Notify BAS (Building Automation System) of Functions and Alarms

This control allows for simple and reliable interface with the BAS via dry contact closures so the BAS can monitor the unfired steam generator from a remote location. The BAS can also start and stop the packaged water heater.