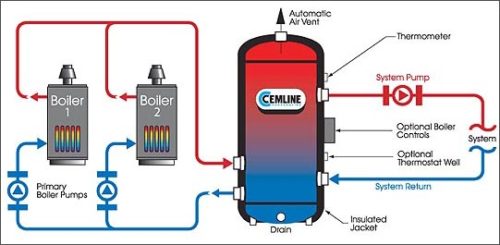

System Efficiency Buffer Tank (SEB Series) CEMLINE® Primary/Secondary Buffer Tank, Air Separator

- Improves Efficiency of the Heating System

- Eliminates the Need for an Air Separator

- Primary/Secondary Hydraulic Separator

Cemline primary/secondary buffer tanks improve system efficiency by preventing the problem of short cycling boiler(s).

Low water content boilers operating at low loads will short cycle leading to sooting, premature component failure, and nuisance shut downs. If the boiler is allowed to fire for a minimum of several minutes the full efficiency of the boiler can be achieved preventing sooting, premature component failure, and nuisance shut downs.

Boiler systems are sized to heat the building on the coldest days. When the outside temperature is above minimum outside design conditions the boiler may only require a short period of firing to warm the building causing short cycling of the boiler. Installing a Primary/Secondary buffer tank prevents this short cycling. Many boiler manufactures do not recommend firing the boiler(s) more than 6 cycles per hour.

Cemline primary/secondary buffer tanks remove air from the heating system, thus eliminating a separate air separator.

Boiler systems require a low velocity area in the system to allow entrained air to be separated from the boiler water. A Primary/Secondary Buffer tank will have extremely low velocity and is used as the air separator, thus eliminating the need for a separate air separator.

Cemline primary/secondary buffer tanks act as a hydraulic separator by separating the primary and secondary sides of the boiler system.

The primary/secondary hydraulic separator allows for variable volume systems to operate with the modern boiler as instructed in ASHRAE 90.1.

Cemline Primary/Secondary buffer tanks come complete with insulated jackets [R-12.5] with Velcro closures for simple field installation.

Cemline Primary/Secondary buffer tanks have a well to accept Building automation system or customer supplied temperature sensors. As an option a factory supplied digital electronic thermostat can be supplied to cycle the boilers on call for heat. This digital electronic thermostat has a LCD temperature display and can be easily field programmed for a minimum of 2 oF and maximum of 30 oF temperature differences.

The SEBs are vertical tanks, which come in 120, 200, 300, and 500-gallon capacities. The standard options on an SEB include ASME Pressure vessel (125 psi working pressure @400 F), an air vent, a field installed insulated jacket, and thermometer. Optional equipment is a digital electronic programmable thermostat.