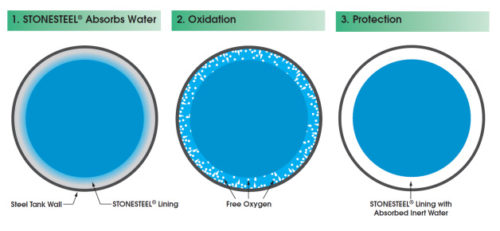

A STONESTEEL® Tank is constructed with a steel shell which completely supports a uniform, water resistant lining of hydraulic STONESTEEL®. The rusting and corrosion common with steel tanks is prevented because the water touches only non-corrosive surfaces. The STONESTEEL® is applied in a continuous arch against the metal wall and will not be injured by ordinary use or handling.