This water heater is the perfect solution for installations where space is at a premium. These units can produce high water volumes with temperature control of +/- 4 oF at fluctuating building loads. The SSH Series water heaters have a small 30, 45, or 60 gallon stainless steel vessels and are great for replacement of existing heaters.

-

Standard Equipment

ASME Code Constructed National Board Registered Storage Tank

CEMLINE® tanks are designed and constructed in accordance with the latest A.S.M.E. Code regulations using pressure vessel quality plate and certified welders. An A.S.M.E. code certificate is provided and all vessels are registered with the National Board of Boiler and Pressure Vessel Inspectors. Vessels are normally built for 125 psig maximum working pressure but can be furnished for pressures as low as 15 psig and as high as 500 psig.

Stainless Steel Tank

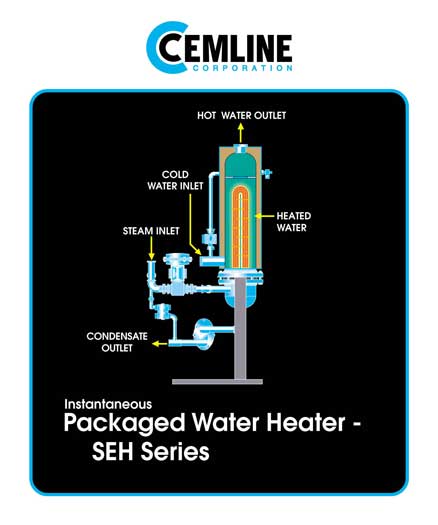

CEMLINE SEH water heaters are constructed with a solid 316-L grade stainless steel vessel. 316-L stainless steel is acknowledged as the most corrosive resistant stainless used for water heaters. CEMLINE SEH with 316-L stainless steel vessels will give the customer many years of service without concern of corrosion or tank failure.

Stainless Steel Threaded Connections

CEMLINE SEH water heaters are constructed with solid 316-L stainless steel openings. This grade of stainless steel was chosen for its proven long life and corrosion resistance.

2" Foam Insulation

CEMLINE heaters are furnished with 2″ thick foam insulation. This high quality insulation conforms to the latest ASHRAE standards for commercial water heaters, and has proven to be an extremely reliable means of minimizing heat loss.

20 Gauge Steel Jacket with Hammertone Enamel Finish

CEMLINE packaged units are neatly and attractively covered with a 20 gauge steel jacket over the Fiberglass insulation. The jacket protects the insulation, and is professionally painted with superior quality enamel to allow the added importance of an easy to maintain surface.

Structural I-beam Support Skid Base

CEMLINE heaters are mounted on structural I-Beam support skids designed as a permanent base. This skid is pre-engineered to allow correct support for the heater.

ASME Relief Valve- pressure and temperature

CEMLINE packages are provided with ASME pressure-temperature relief valves sized to relieve the total BTU input of the heating coils.

Digital Thermometer

CEMLINE heaters are provided with a digital tank thermometer with LCD readout to monitor temperature of the water within the vessel. The thermometer will be console mounted with a compound steam pressure gauge to monitor steam pressure at the coil. (Units heated with boiler water will be supplied with a boiler water thermometer to monitor temperature of incoming boiler water).

Water Pressure Gauge

CEMLINE packaged heaters are supplied with a large, easily readable pressure gauge.

Control Valve

CEMLINE package units are offered with several options of control, depending on specific requirements or desired preferences. Valves can be provided of the pilot operated, pneumatically operated or electronic type. Control valves are factory sized and installed so the owner may rest assured that the valve provided with the heater is correctly fitted and engineered to meet the specific job requirements.

U-Bend Heating Coil, Rolled into Copper Lined Tube Sheet

CEMLINE manufactures a complete line of boiler water, steam, and high temperature hot water heating coils, which are constructed of copper or copper nickel or stainless steel tubing. The tube sheets for these coils are copper lined, and units provided with circulating pumps are designed with a copper wrapper surrounding the coil to provide an efficient means of providing the best heat transfer from the coil to the water to be heated. Recovery systems are quickly and efficiently sized to handle specific load requirements to meet any need.

Integral Bronze Circulator

Bronze fractional circulating pump circulates the water over the coil, thereby maximizing the heat transfer efficiency of the coil. The pump is selected to match the operating conditions of the water heater.

Single Solenoid Safety System

Standard Safety System

This is an over-temperature safety system which will close the main control valve upon an over-temperature condition. This system utilizes a digital electronic adjustable thermostat with LCD readout which monitors the temperature of the water and if an over-temperature condition is detected, sends an electric signal to the valve, thereby closing the valve. This system requires a 120 volt 5 amp circuit.Solid State Operating Control

The CEMLINE CEM-TROL® incorporates operating and limit functions in one solid state controller. The controller features a LED display of the temperature and on board operating PID temperature control along with high temperature safety cut offs and alarm indications. The CEM-TROL® simplifies the control of the Packaged Water Heater, enhances the look of the product, and follows industry trend to solid state controls.

Alarm Bell

An alarm bell is furnished to sound an alarm in the event that either the primary or secondary high temperature limits are exceeded. An alarm silencing relay allows manual pressing of a button to silence the alarm bell, but red warning light remains on until the alarm condition is corrected.

Remote Start/Stop

This feature allows the Packaged Water Heater to be started or stopped from a remote location. Typically this would be accomplished from the Building Automatic System (BAS). Requires a dry contact suitable for 24 Vac and 1 amp.

-

Components

STEAM AS THE ENERGY SOURCE

STANDARD EQUIPMENT

CONTROL VALVE

Pilot Operated

A pilot operated valve can only be used with steam as the energy source. Pilot operated valves use steam pressure as the energy source to modulate the control valve. Steam from upstream of the valve is directed into a pilot valve. This pilot valve has an adjustable set point and temperature sensing bulb in the heated water. The pilot valve compares the set point to the sensed temperature and regulates the amount of steam passing through the pilot to the diaphragm in the bottom of the control valve.The steam pressure on the diaphragm opens to the downstream side of the valve. When the pilot valve senses the desire temperature is reached it closes; this does not allow any more steam to pressurize the diaphragm in the bottom of the control valve. The bleed line allows any steam pressurizing the diaphragm to be relieved and the valve closes.

Pneumatic (Air) Operated Control Valve

Air operated valves use building control air pressure to modulate the control valve. The air signal is brought to an adjustable set point temperature sensing controller with a temperature sensing bulb in the heated water. The temperature sensing controller compares the set point to the sensed temperature. The controller regulates the amount of air that passes to the pneumatic actuator of the valve to modulate the valve. This allows steam to pass into the heater coil to maintain the set point of the controller. When the set point is achieved, no air is passed through the temperature sensing controller and the valve is closed. In the event of high temperature or loss of building power, the limit control shall close the air line to the valve and vent any air in the actuator to atmosphere which closes the valve.

Electronic Control Valve

Electronically operated control valves use a solid state temperature sensor which is wired to an electronic control module. The electronic control module has an adjustable set point. The control module compares the set point with the sensed temperature and sends an electric signal to a magnetic linear actuator on the control valve. The magnetic linear actuator modulates the control valve and regulates the amount of boiler water through the valve to maintain the set point of the controller. When the set point is achieved, the controller sends a signal to the valve actuator and the valve closes. In the event of high temperature loss or loss of building power, the limit control closes the electric power to the controller which closes the valve.

Steam Traps

CEMLINE provides float and thermostatic traps for both the drip and main trap. Float and thermostatic traps are acknowledged as the correct traps to use with continuously modulating control valves. Float and thermostatic traps provide immediate drainage of condensate and include a built in thermostatic air vent for venting air. The drain orifice is designed to provide a water seal and eliminate the loss of any live steam under all load conditions. Float and thermostatic traps should not be used to lift condensate.

Inlet Stream Strainer

Strainers are “Y” type with blow down connection and easily removable stainless steel strainer screen.

Source Steam Pressure Gauge

Large, easily readable pressure gauges to read both the source and generated steam pressure.

Vacuum breaker

A vacuum breaker will be mounted in the coil head and will break any vacuum which might occur when the steam is condensed.

OPTIONAL EQUIPMENT

Double Solenoid Safety System

An optional safety system, which will deactivate the main control valve as described in solenoid safety system, will also activate a second solenoid valve to drain excessively heated water. The controller is designed to permit different set points for the valve closure and draining.

Double Wall Coil

Double wall coils have inner and outer tubes with a vented leak path. If either the inner or outer tube fails, no cross contamination of potable water is possible and a visible indication of the leak will show. Double wall coils are only available in 3/4″ OD tubing.

BOILER WATER AS THE ENERGY SOURCE

STANDARD EQUIPMENT

CONTROL VALVE

Pneumatic (Air) Operated Control Valve

An air operated valve can be used with hot water as the heating medium. Air operated valves use building control air pressure to modulate the control valve. The air signal is brought to an adjustable set point temperature sensing controller with a temperature sensing bulb in the heated water. The temperature sensing controller compares the set point to the sensed temperature. The controller regulates the amount of air that passes to the pneumatic actuator of the valve to modulate the valve. This allows boiler water to pass into the heater coil to maintain the set point of the controller. When the set point is achieved, no air is passed through the temperature sensing controller and the valve is closed. In the event of high temperature or loss of building power, the limit control shall close the air line to the valve and vent any air in the actuator to atmosphere which closes the valve.

Electronic Control Valve

Electronically operated control valves use a solid state temperature sensor which is wired to an electronic control module. The electronic control module has an adjustable set point. The control module compares the set point with the sensed temperature and sends an electric signal to a magnetic linear actuator on the control valve. The magnetic linear actuator modulates the control valve and regulates the amount of boiler water through the valve to maintain the set point of the controller. When the set point is achieved, the controller sends a signal to the valve actuator and the valve closes. In the event of high temperature or loss of building power, the limit control closes the electric power to the controller which closes the valve.

Electronic Control Valve

Electronically operated control valves use a solid state temperature sensor which is wired to an electronic control module. The electronic control module has an adjustable set point. The control module compares the set point with the sensed temperature and sends an electric signal to a magnetic linear actuator on the control valve. The magnetic linear actuator modulates the control valve and regulates the amount of boiler water through the valve to maintain the set point of the controller. When the set point is achieved, the controller sends a signal to the valve actuator and the valve closes. In the event of high temperature or loss of building power, the limit control closes the electric power to the controller which closes the valve.

Two Way Valve

A two way valve modulates from fully closed to fully open varying the amount of hot water circulated through the coil to maintain the desired output temperature. When closed the two way valve may cause a change in the heating water loop pressure.

Three Way Valve

A three way valve modulates from directing all heating water through the coil to directing no heating water through the coil, varying the amount of hot water circulated through the coil to maintain the desired output temperature. The pressure drop in the heating system will be relatively constant with a three way valve.

OPTIONAL EQUIPMENT

Double Solenoid Safety System

An optional safety system, which will deactivate the main control valve as described in solenoid safety system, will also activate a second solenoid valve to drain excessively heated water from the heater. The controller is designed to permit different set points for the valve closure and draining.

Double Wall Coil

Double wall coils have inner and outer tubes with a vented leak path. If either the inner or outer tube fails, no cross contamination of potable water is possible and a visible indication of the leak will show. Double wall coils are only available in 3/4″ OD tubing.

-

CEM-TROL II

Buit-in PID Control Signal

PID Control Signal used to modulate an electronic control valve or to control I-P transducer modulating an air operated control valve. The PID controller allows for precise pressure control of the unfired steam generator.

Built-In LCD Touch Screen Display

The CEM-TROL®II features an easy to read and operate LCD touch screen display. The CEM-TROL®II display indicates temperature set point, operating temperature, and PID voltage output. The CEM-TROL®II touch screen display has an easy to navigate menu system for adjusting the settings of the water heater.

Built-in On-Off Switch

Allows for local on-off and is convenient for service in the unlikely event service is required.

Built-in Alarm Horn

The alarm horn will sound and fault LED will light on high temperature or secondary high temperature. The CEM-TROL also features an alarm silence relay which will silence the alarm but not the fault light when the generator is being serviced. When the fault is cleared, both the alarm and fault light will automatically reset.

Built-in Single Point Wiring

If the timed blowdown option is selected, the interval and duration of blow down can easily be selected in the STEAM-TROL®.

Built-in Operating Temperature Readout

The STEAM-TROL® operates in conjunction with the level control to signal the feedwater solenoid or feedwater pump to maintain the correct water level in the unfired steam generator.

Built-in High Temperature Set Point

The STEAM-TROL® operates in conjunction with the level control to signal the to a modulating feedwater valve to maintain the correct water level in the unfired steam generator.

Built-in Secondary High Temperature Set Point

The STEAM-TROL features an easy to read LCD digital readout of the operating pressure.

Built-in Remote Temperature Setting

In the event of high pressure the STEAM-TROL® will close the source steam or HTHW supply valve and sound an alarm.

Built-in LED Display of Functions and Alarms

The CEM-TROL® is designed for the user to tell at a glance how the system is operating. The built in LED displays make troubleshooting simple.

Built-in MODBUS RTU to communicate with BAS (Building Automation System) of Functions and Alarms

This control allows for simple and reliable interface with the BAS via MODBUS RTU via a RS-485 connection so the BAS can monitor the water heater from a remote location.

Built-in Contact to Notify BAS (Building Automation System) of Functions and Alarms

This control allows for simple and reliable interface with the BAS via dry contact closures so the BAS can monitor the packaged water heater from a remote location. The BAS can also start and stop the packaged water heater.

- CUT-AWAY