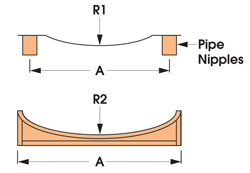

Sizing CEMLINE Steel Tanks are manufactured in a wide range of sizes. Tank diameter is the outside diameter and length refers to the overall tank length.

Material CEMLINE tanks are normally constructed of pressure vessel quality carbon steel. Stainless Steel in grades 304 or 316 and 90:10 CuproNickel can be furnished. Consult factory for other materials.

Exterior CEMLINE Steel Tanks are normally furnished with factory primed exterior. Special paints and coatings are available upon request.

Paint Coatings CEMLINE tanks can be furnished with interior or exterior coatings to meet customer specifications.

Construction CEMLINE Steel Tanks are manufactured in strict accordance with ASME code requirements and National Board Registration. Non-Code tanks are also available.

Working Pressure CEMLINE Steel Tanks can be built in accordance with working pressures designed to suit particular jobs. Tanks are usually built 125 psig working pressure, but tanks with working pressure from 0 to 500 psig can be provided.

Galvanizing CEMLINE tanks through 60″ diameter can be hot dip galvanized at customer request.